Open single crankshaft precision punch

Open Double crankshaft precision punch

Semi-closed single crankshaft precision punch

Close single-crankshaft precision punch

Closed double point crankshaft precision punch

Close double-crankshaft precision punch

Open single point servo model

Gantry dual point servo model

Special machine for open double crankshaft battery shell

Closed single point high speed punch

Three post guides high-speed precision punch

Gant Type Speed Precision Four Post Guider Press Machine

Straight Column Type Four-points ecdenttric press machine

Split and close double-crankshaft precision press machine

- Tel: 400 100 5226

- Fax: 0510-68392919

- E-mail: sherry@yisto-east.com

- Address: No.422, Xizhang Road, Gushan Town, Jiangyin, Wuxi, China

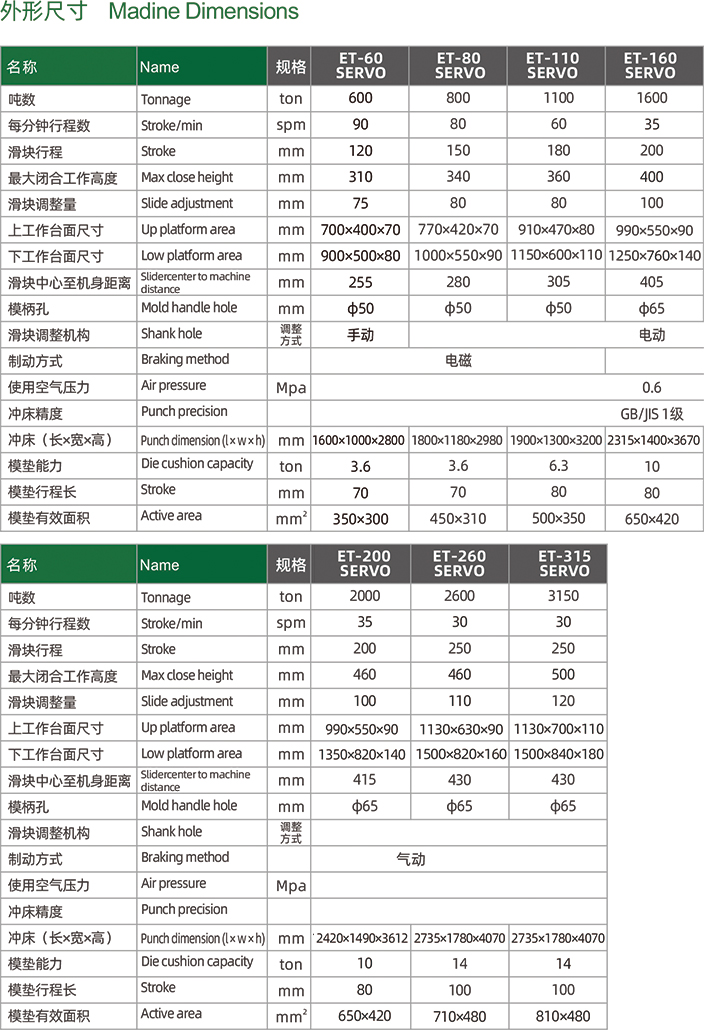

Open single point servo model

Release date: 2024-08-15 14:00:23 Visits: 537

Performance feature

● In order to realize the agile variable-speed motion and torque capability required for servo presses, our newly developed servo motor has been redesigned from a square motor. This redesign increased the maximum output by 150%.

● The servomotor is capable of low sliding speeds inside the forming zone and high sliding speeds outside the forming zone to realize “variable-speed motion,” resulting in better part formability and higher productivity. Various machining methods such as “pendulum motion” can now be used to realize high-speed production.

● The “Silent Deceleration” function allows a “soft touch” at the start of molding, significantly reducing molding noise and vibration and extending mold life. When the high-speed operation mode is selected, it is possible to achieve higher productivity through full-stroke or longitudinal motion while maintaining the same speed in the molding zone.

Standard configuration

|

● Customized low-speed high torque servo motor ● High power servo driver ● Touch screen ● Free setting of operating mode ● Fine adjustment of the main motor handwheel ● Oil pressure overload protection device ● Electric mold height adjustment device |

● Digital modulus height indicator ● Slider and mold balancing device ● Air source connector ● Air blowing device ● Misdelivery detection device ● Power socket ● Electric butter device ● Photoelectric safety protection device ● Machine tool damping device |

Optional configuration

|

● Slider magnetic grating detection device ● Automatic adjustment device for mold height ● Dynamic dead center compensation device ● High frequency quenching of slider guide rail ● Pneumatic mold pad device |

● Servo mold pad device ● Quick mold changing device ● Mold photo device ● Upper feeding device of the slider ● NC feeder ● Leveling machine ● Stamping manipulator |

Previous: Gantry dual point servo model